Dream server incl.

Windows Server 2022 Essentials

Rack system, tower or microserver? You decide!

We started with the objective of developing a practical, robust system for bringing liquid cooling to servers – one that could be scaled from installations with as few as eight mainboards up to medium-sized data centers.

The core of the system is comprised of cooling elements for server mainboards, network components and PSUs. The mainboard cooling elements in the Hot Fluid® system cover the entire board, are made of milled aluminum and are hermetically sealed. Channels inside the cooling elements transport the liquid to the board's heat sources.

The direct contact of the cooling surface with the heat-generated components on the mainboard prevents the development of hot spots within the server. In contrast to conventional air cooling, heat is evenly dissipated. The cooling elements have connectors for drip-proof, air-tight connections. Removable cooling elements for the RAM modules ensure that memory can be easily expanded or exchanged.

Although server components have longer life cycles than consumer hardware, they do eventually require replacing. When these are replaced, new cooling elements are also required. We have developed a process that allows the system to be quickly adapted to new hardware and therefore protect your investment.

The mainboards are powered by high-performance central PSUs. These, too, are liquid-cooled. One PSU can power up to eight mainboards. Redundant setups are also possible. The PSUs are equipped with high-voltage direct current inputs, so that they can be powered by alternative energy sources like photovoltaics or wind power systems with low conversion losses.

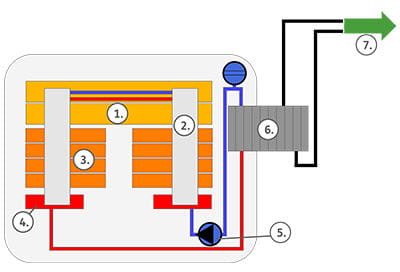

1. Network components (Infiniband, Ethernet, ...)

2. Connector block with integrated channels

3. Compute nodes

4. PSUs 3KW AC/DC & DC/DC

5. Circulation pump

6. Plate heat exchanger

7. Connection to building services

Water pipes running through a server: For many technicians, this sets off alarm bells. That is why the Hot Fluid® system was constructed to provide maximum protection for the hardware while requiring minimum maintenance. There are no weld points that deteriorate thermally or mechanically. Individual components like mainboards are connected without tools to the cooling system via a guaranteed drip-proof, air-tight port.

The connection between the cooled components and the cooling circuit is provided by a central system at the rear of the system. Mainboards and switches can be connected at the front to the system's power and water supply without any need for tools. The system is low maintenance since it does not require any hydraulic balancing. Management and monitoring are done with open source products.

You can contact us at any time for more information.